Infrastructure-Independent

Hybrid Architecture.

Designed for real roads, real loads, and real constraints.

Designed for real roads, real loads, and real constraints.

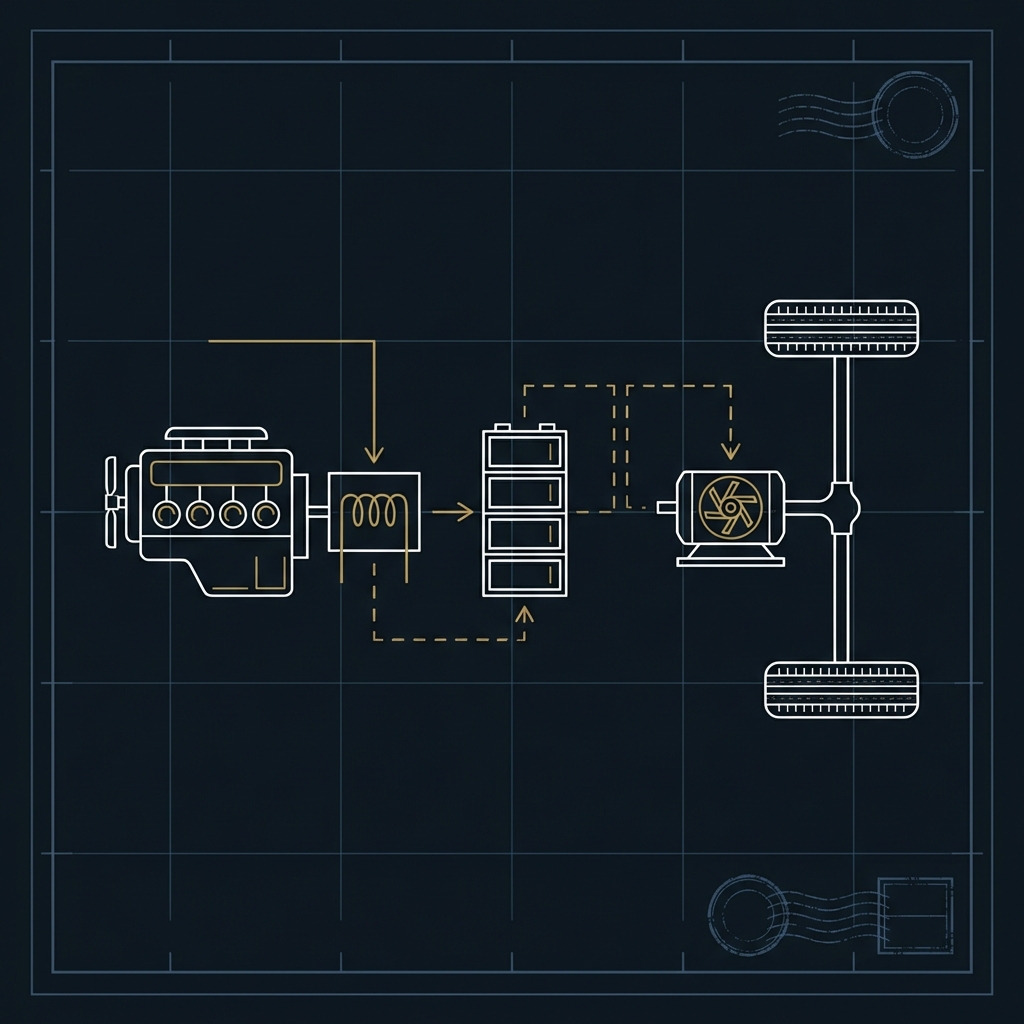

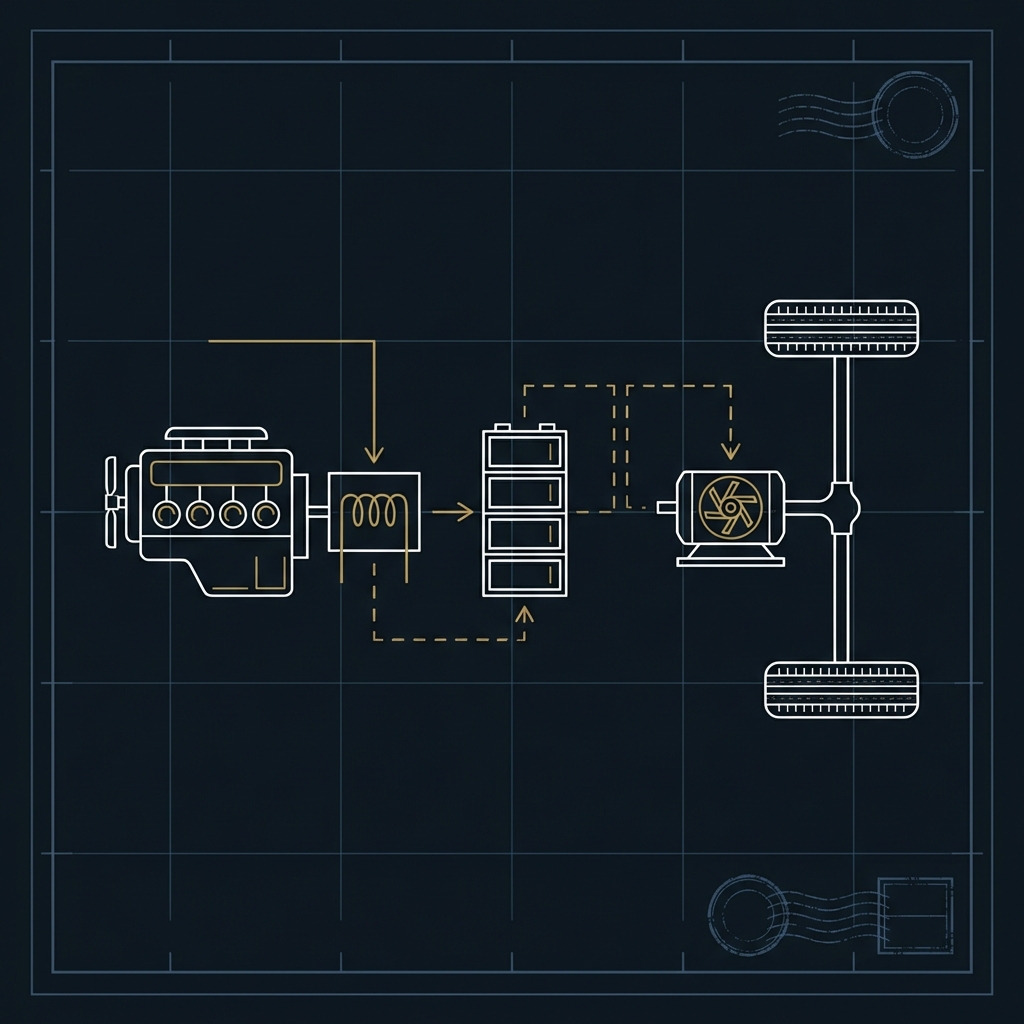

We follow a series hybrid architecture where the wheels are driven ONLY by the electric motor.

"This reduces mechanical complexity by removing the transmission and clutch from the engine load path, significantly lowering maintenance costs."

Designed for the Indian climate. Liquid cooled thermal management ensures safety and longevity even in 45°C ambient temperatures. High cycle life chemistry logic prioritized for commercial usage patterns.

Permanent Magnet Synchronous Motor (PMSM) delievering instant torque for heavy payloads. Regenerative braking captures energy typically lost during stop-and-go city traffic.

A compact, fixed-RPM generator that automatically engages when battery state-of-charge (SoC) drops below a threshold. It operates at the engine's most fuel-efficient point, ignoring road speed variations.

The brain of the system. Model-based design algorithms manage the energy split between battery and generator to maximize TCO (Total Cost of Ownership).